Howdy, Y’all!

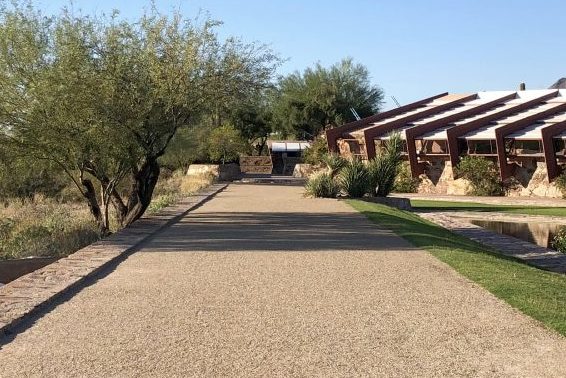

Decomposed granite (DG) is a natural byproduct of weathering and erosion of granite. It comes in a variety of colors and can be screened to sort the particles by size.

When quarried, decomposed granite is loose and sandy, but forms a durable and stable surface when compacted. This is thanks to its high content of fines (clay and silt) that binds the gravel together. However, gravel stabilizer, binder, or soil palliative can be added for increased stability.

Stabilizers help control dust and erosion, reduce the tracking of material indoors, and prevent weeds from taking root.

Some products like resin and wax polymer binders, create surfaces comparable to concrete or asphalt once cured. Most binders expand when wet, locking the gravel in place and preventing washouts. Others like calcium chloride absorb moisture from the air, damping the surface.

Stabilized DG benefits

Stabilized decomposed granite has more benefits than you can shake a stick at.

You can enhance and maintain the natural color and texture of your DG and prevent it from shifting around. The stabilized surface is resistant to wear cutting down on repair. What’s more, you also put the kibosh on dust and weed growth.

Types Decomposed Granite Stabilizers

There are several types of stabilizers available:

- Moisture-absorbing salts, including magnesium, calcium, and sodium chloride

- Organic non-petroleum products derived from vegetable oils and animal fats.

- Petroleum-based stabilizers such as asphalt, tar, and oil

- Resins such as lignosulfonates (tree sap) and synthetic polymer emulsions like polyvinyl acetate and vinyl acrylic

- Clay additives like bentonite and montmorillonite

- Portland or soil cement

Note: Some manufacturers might use different trade names for their products.

Moisture absorbing Chlorides

Most gravel stabilizers are calcium, magnesium, and sodium chloride salts.

- Calcium chlorides come in both powder and liquid form

- Magnesium chlorides come in liquid form. These two are highly effective even in low humidity conditions.

- Sodium chloride is not used as much and is considered the least effective.

These salts are hygroscopic, meaning they draw moisture from the air to keep that decomposed granite damp.

Moisture-absorbing binders can be sprayed on the surface or pre-mixed into the gravel before installation. For a spray-on stabilizer, apply it on the loose and evenly spread DG surface before compacting. You can use a calibrated pressurized sprayer or watering can. But if the gravel is already compacted, scarify and open the surface with a rake before the chloride emulsion is sprayed on.

The gravel will appear darker due to the moisture content, and the application can last up to six months or until the first significant rainfall washes the product. If the gravel doesn’t have good gradation, the chlorides will be wasted and short-lived.

Resins & Polymers

Resins are a by-product of the pulp milling industry. Their main constituent is lignin sulfonate – a fancy way of saying “tree sap.” These lignin binders are dark brown and super sticky.

Now, there are a couple of ways to use resins – either dilute them and apply them as a surface treatment or mix them in with the gravel before application.

Liquid or wax polymers can be mixed in with the decomposed granite or crushed granite before laying. But fair warning – they don’t perform as well in moist or freezing conditions.

Once that polymer or resin binder has cured, it gets just as hard as concrete or asphalt and lasts for a few years.

Organic Non-Petroleum Oil

One product that is popular with decomposed granite stabilization is Organic Lock. This is a non-petroleum oil binder made from all-natural, biodegradable vegetable and plant oils and animal fats. It has similar properties to petroleum-based oils and is a great eco-friendly option.

You can either spray it on the surface of the gravel or pre-mix it.

Petroleum oil products

Petroleum products like liquid or emulsified asphalt are made from bitumen, a byproduct of the oil refining process.

Emulsified asphalt is a blend of liquid asphalt, an emulsifying agent, and water, and is a good choice for sealing a decomposed granite driveway. However, it might not bond well if sprayed on the surface. It requires special application equipment before another uniform layer of gravel is spread on top to cover and bind to the tar.

Be careful not to use petroleum-based oils close to drinking water supplies. Before using any petroleum oil stabilizers, check with local regulatory agencies like the DEP or EPA for approval.

Natural Clay Additives

In some parts of the country, you will find natural clay deposits like bentonite and montmorillonite with a high plasticity index. These can improve the cohesion of decomposed granite particles.

They work pretty well when the weather is dry, but in wet conditions, they may not hold up as well. It can be a real challenge to keep the surface dust-free in dry weather. In addition, hauling clay to the job site and blending it is quite a task. You must be careful to add just the right amount.

Portland/Soil Cement

Now, this option is not cheap, but it’s well worth the effort since it provides long-term stability.

If you’re an average homeowner with a few bags of concrete, you could create a 15:1 DG to the concrete mixture, spread it, water it, and compact it. Just remember, though, that cement might alter the color of the DG.

How to stabilize decomposed granite

There are two main forms of stabilizers – powdered or liquid.

- For powdered stabilizers, mix it into the dry DG aggregate, add water, and spread it. Then, wet it, compact it, and let it cure for about 48 hours. Most powdered stabilizers like OrganicLock recommend using around 8 to 12 pounds per ton of DG. Mix it in a debris-free spot and check the moisture level by compressing it into a ball in your hands. If it doesn’t stick together, add water. If it’s too shiny, it’s too wet. The sweet spot is somewhere in between where the ball retains its shape but looks relatively dry.

- Liquid stabilizers are diluted with water and sprayed on the DG surface before compacting.

- Pellet or flake stabilizers also exist. These are to be spread on the gravel surface before watering and compacting.

You can add a stabilizer on-site or off-site. The application rate depends on the product. Many companies offer premixed stabilized DG, so you don’t have to do it yourself.

Rolling the surface can help, but be careful as the gravel might come off and cause unevenness.

There you have it folks. Until next time!